Picostrain Strain Gage Circuits

PS09 PICOSTRAIN

Compact System-on-Chip for Strain Gage Applications

The PS09 is the latest member in the PICOSTRAIN product family of integrated circuits for measuring strain gauges.

It represents the next step towards higher integration and improved functional density.

The PS09 takes the full advantage of the PICOSTRAIN digital measuring principle and allows very compact and cost effective designs with very few external components. It perfectly suits to systems and instrumentation where the result should be provided digitally, via SPI, IIC or UART. Such as system is for instance a Digital Load Cell (DLC) which directly integrates the electronics into the sensor and comes with many benefits therefore, e.g. good EMI behavior, compact design, easily applicable temperature compensation, etc.

PicoStrain: Strain Gauge / Load Cells

Industrial Applications

- Digital load cells

- Torque wrenches

- Pressure indicators

- Legal for trade scales

- Couting scales

Consumer Applications

- Pure solar driven scale

- Body scales

- Kitchen scales

- Pocket scales

- Hanging scales

- Postal scales

- Package scales

PICOSTRAIN PS09 Features

Compact System-on-Chip for Resistive Bridge Sensors

General Circuit Features

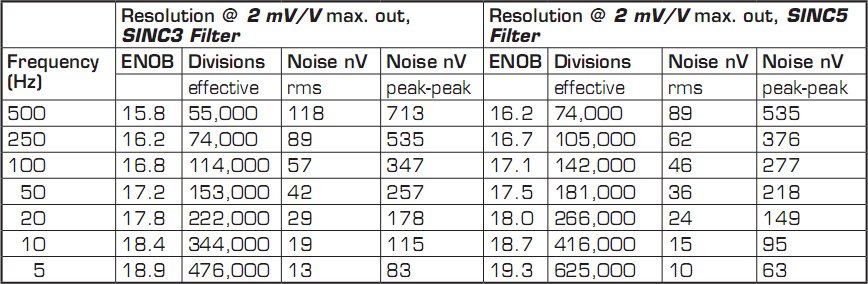

- PICOSTRAIN Front-End with up to 150,000 peak-peak divisions (@2mV/V)

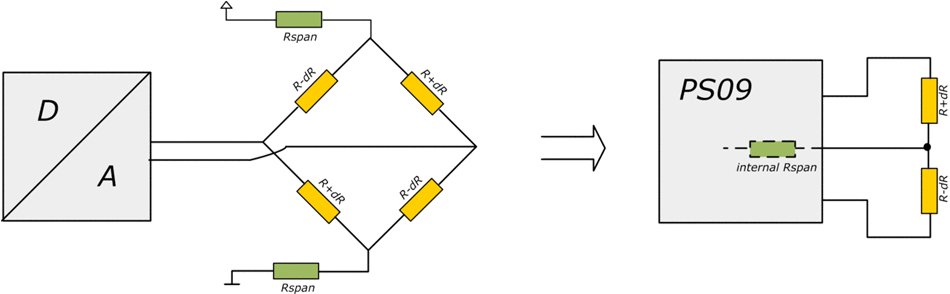

- Capability to measure half-bridges, full-bridges, quattro-bridges

- Integrated analogue switch for direct driving of Wheatstone-bridges

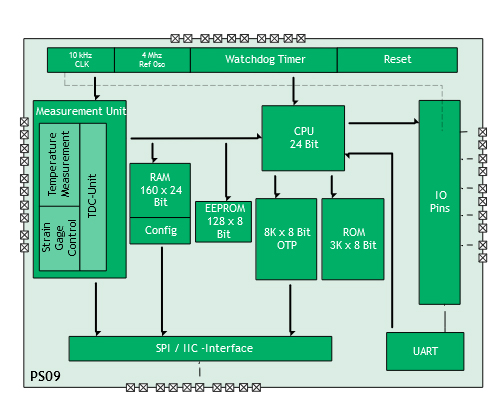

- Microprocessor with 24-Bit data structure and 8 k ROM (OTP)

- Embedded very low current 10 kHz oscillator (300 nA)

- Standby current with timer active < 2 µA

- Driver for external 4 MHz ceramic oscillator

- 8 GPIOs, up to 24 programmable I/O-ports

- 4 capacitive switch inputs

- external LCD driver support

- Embedded temperature measurement and temperature compensation

- Embedded bandgap voltage reference for low battery detection

- Watchdog timer

- Serial SPI and IIC interfaces

- UART interface (for RS232, RS485)

- Supply voltage 2.1 to 3.6 V

- As dice or packaged (QFN40)

FUNCTIONAL BLOCK DIAGRAM

PS09 Specification

- Resolution: up to 28 Bit (RMS)

- Max. data rate: 1kSPS

- Power supply voltage: 2.1 V to 3.6 V

- Operating temperature: -40 °C to 125 °C

- Current consumption: typ. 0.39 mA at maximum speed or 0.005 mA t low current configuration

- Standby current:~ 0.001 mA

- INL: 1.25 ppm (@ 3 V to 3.6 V supply Voltage)

- Offset drift:

- PSSR: 130 dB (@3,3 V)

- Offest Drift: 0,01ppm/K

- Gain-Drift: typ. 1ppm/K (Total system with 350 ω Strain Gauge, 5V)

CONVERTER PERFORMANCE

Additional Information

Documentation & Downloads

Datasheet

|

DescriptionDatasheet PS09 Vol. 2: |

Version |

Size |

Download |

|

DescriptionDatasheet PS09 Vol. 1: |

Version |

Size |

Download |

|

Description |

Version |

Size |

Download |

Description |

Version |

Size |

Download |

|

Description |

Version |

Size |

Download |

DescriptionDatasheet PS081: Enhanced Single-chip solution for weigh scales |

Version |

Size |

Download |

|

Description |

Version |

Size |

Download |

|

Description |

Version |

Size |

Download |

|

Description |

Version |

Size |

Download |

Application Notes

|

DescriptionApplication Note 030: |

Version |

Size |

Download |

|

DescriptionApplication Note 025: |

Version |

Size |

Download |

|

DescriptionApplication Note 023: |

Version |

Size |

Download |

|

DescriptionApplication Note 022: |

Version |

Size |

Download |

|

DescriptionApplication Note 021: |

Version |

Size |

Download |

|

DescriptionApplication Note 018: |

Version |

Size |

Download |

|

DescriptionApplication Note 012: |

Version |

Size |

Download |

|

Description |

Version |

Size |

Download |

White Papers

|

DescriptionWhite Paper 004: |

Version |

Size |

Download |

|

DescriptionWhite Paper 003: |

Version |

Size |

Download |

|

DescriptionWhite Paper 002: |

Version |

Size |

Download |

|

DescriptionWhite Paper 001: |

Version |

Size |

Download |

Screencasts

|

DescriptionScreencasts PS09: |

Version |

Size |

Download |

|

DescriptionScreencasts PS09: |

Version |

Size |

Download |

|

DescriptionScreencasts PS09: |

Version |

Size |

Download |

|

DescriptionScreencasts PS081/PS09: |

Version |

Size |

Download |

|

DescriptionScreencasts PS08/PS081: |

Version |

Size |

Download |

|

DescriptionScreencasts PS08-EVA-KIT: |

Version |

Size |

Download |

Software

|

Description |

Version |

Size |

Download |

|

Description |

Version |

Size |

Download |

|

Description |

Version |

Size |

Download |

|

Description |

Version |

Size |

Download |

|

DescriptionSoftware National Instruments: |

Version |

Size |

Download |

|

DescriptionSoftware National Instruments: |

Version |

Size |

Download |

|

DescriptionSoftware National Instruments: |

Version |

Size |

Download |

Datasheet

|

DescriptionDatasheet PS09 Vol. 2: |

Version |

Size |

Download |

|

DescriptionDatasheet PS09 Vol. 1: |

Version |

Size |

Download |

|

Description |

Version |

Size |

Download |

Description |

Version |

Size |

Download |

|

DescriptionDatasheet PS081 Eval System: |

Version |

Size |

Download |

DescriptionDatasheet PS081: Enhanced Single-chip solution for weigh scales |

Version |

Size |

Download |

|

Description |

Version |

Size |

Download |

|

Description |

Version |

Size |

Download |

|

Description |

Version |

Size |

Download |

Application Notes

|

DescriptionApplication Note 030: |

Version |

Size |

Download |

|

DescriptionApplication Note 025: |

Version |

Size |

Download |

|

DescriptionApplication Note 023: |

Version |

Size |

Download |

|

DescriptionApplication Note 022: |

Version |

Size |

Download |

|

DescriptionApplication Note 021: |

Version |

Size |

Download |

|

DescriptionApplication Note 018: |

Version |

Size |

Download |

|

DescriptionApplication Note 012: |

Version |

Size |

Download |

|

Description |

Version |

Size |

Download |

White Papers

|

DescriptionWhite Paper 004: |

Version |

Size |

Download |

|

DescriptionWhite Paper 003: |

Version |

Size |

Download |

|

DescriptionWhite Paper 002: |

Version |

Size |

Download |

|

DescriptionWhite Paper 001: |

Version |

Size |

Download |

Screencasts

|

DescriptionScreencasts PS09: |

Version |

Size |

Download |

|

DescriptionScreencasts PS09: |

Version |

Size |

Download |

|

DescriptionScreencasts PS09: |

Version |

Size |

Download |

|

DescriptionScreencasts PS081/PS09: |

Version |

Size |

Download |

|

DescriptionScreencasts PS08/PS081: |

Version |

Size |

Download |

|

DescriptionScreencasts PS08-EVA-KIT: |

Version |

Size |

Download |

Software

|

Description |

Version |

Size |

Download |

|

Description |

Version |

Size |

Download |

|

Description |

Version |

Size |

Download |

|

Description |

Version |

Size |

Download |

|

DescriptionSoftware National Instruments: |

Version |

Size |

Download |

|

DescriptionSoftware National Instruments: |

Version |

Size |

Download |

|

DescriptionSoftware National Instruments: |

Version |

Size |

Download |

PICOSTRAIN Measurement Principle

The capacitor is charged to the supply voltage and then discharged through one of the SG resistors. The discharge time down to an arbitrary trigger level is measured with ultra-high precision using a TDC (Time-to-Digital Converter). The discharge time is in the range 100 µs. The TDC unit used have a typical single-shot resolution of less than 20 ps.

This measuring process is repeated in time-multiplex with both resistors of a half-bridge, using the same capacitor and the same comparator. Calculating the ratio of the results will turn out the absolute values and temperature dependencies of the capacitor and the comparator.

Additional patented circuits and algorithms inside the products compensate for further error sources like the switch-on resistance of the output drivers (Rdson) and the propagation delay of the comparator. The result is very precise, nearly free of gain errors and very stable with temperature. In total each single measurement is made of 8 discharge/charge cycles to solve this compensation task.

Due to the measuring principle, does not need a full-bridge but a half-bridge is sufficient. The supply of the half-bridge is provided directly by the circuits. There is no need for a separate supply of the SG. Also the reference voltage is not required.

Thanks to the pulsed drive easily controls the current through the whole system and, even more important, reduces the current consumption to remarkably less than comparable ADC systems.

The measuring principle is showing a new approach to strain gauge (SG) measurement. Contrary to the Wheatstone bridge, where the variation of resistance is transformed into a variation of voltage, solutions transfer it into a high-precision time interval measurement. For this purpose the SG resistors are connected to a capacitor, forming a low-pass filter.

Metal strain gages (SG) change their value with mechanical deformation, especially a variation in length. The strain e designates the relative variation in length of the SG:

Strain (e) = dL/L

Common SG have a maximum strain of typical

e(max) = 1000 µ (1000 x 10-6 or 0.1 %).

The ratio of the resistance variation to the length variation is designated K-factor or strain gain.

dR/R = K x dL/

For metal SG the K-factor is typically of value 2. The maxim variation of the SG resistance is then given as:

dR(max)/R = e(max) x K = 2000 ppm

If the SG is connected in the manner of a Wheatstone bridge, this corresponds to a maximum signal output voltage of 2 mV/V. The resistance of common metal strain gauges is typically 350 Ohm or 1000 Ohm. The maximum variation in resistance and therefore the effective measurement range is within 0.7 Ohm to 2 Ohm. This small variation must be resolved according to the measurement task. The range of the resolution needed is very wide. It is between 10 ENOB (e.g. for pressure sensors) and 18 ENOB (e.g. calibrated scales). In the upper range the precision of the measurement has to be:

Resolution : 2000 ppm/218 = 0.008 ppm eff.

or 26.9 ENOB referenced to the full resistance.

The typical measurement rates are in between

2 – 8 Hz (e.g. scales) and

4 – 10 kHz (e.g. fast pressure sensors).

Internal Precision Temperature Measurement

Like other members of the PICOSTRAIN product family PS09 supports the connection of only a half-bridge as sensor without any loss in resolution quality. However, unlike its ancestors the PS09 contains additionally an internal temperature unit which allows a convenient temperature compensation of half-bridge sensors without any additional external compensation resistors. This way, the whole sensor gets simpler and the temperature compensation more convenient than ever before. Here again, especially the Digital Load Cell takes full advantage of this new feature:

Another unique feature is the capability of directly connecting up to 4 capacitive keys, which adds only 1 µA of additional current! This is much less than common solutions for capacitive keys and comes therefore very handy in power-saving applications such as battery-driven devices or pure solar-driven devices, e.g. a solar kitchen-scale.

Get into the technology of the PS09 and discover the world’s most innovative technology for resistive bridge type sensors, which are based on metal strain gauges.

PicoStrain Advantages

Advantage 1

Extremely low current consumption for your complete bridge sensor system

The ultra-low power PICOSTRAIN measuring principle shows an extremely low overall current consumption of the total system. It is possible to reduce the power consumption by a factor 10 to 20 compared to conventional AD-Converter solutions.

Advantage 2

One solution suits to (nearly) all applications, from low cost up to highest precision

PICOSTRAIN allows to build systems with 1.500 … 150,000 peak to peak divisions (at 2 mV/V strain) and update rates up to 1 kHz. One and the same chip covers the requirements of many applications, just by variation of your software.

Advantage 3

Reduced overall system costs

PICOSTRAIN reduces or saves the costs of the power supply. Power plugs will be replaced by batteries, batteries will be reduced in size. In many applications a single coin cell battery may last for 10 years under normal operation. The number of external components is far below the usual.

Advantage 4

New products that could not be done up to now

There are new product options mainly due to the low current consumption and low operating voltage. First to mention are solar driven applications. Also 1.55 V silver-oxide batteries are possible although with some restrictions (e.g. re-programming). The measurement quality is impressive even at those low voltages and it might be difficult to find something comparable in the market.

Advantage 5

Improve your Quality and lower your production cost

PICOSTRAIN offers unique possibilities to simplify the production of your bridge sensor and to improve its quality. The bridge offset can be simply adjusted by setting a register, gain drift can be reduced through software correction of Rspan. This method is more precise than with standard solutions. At the same time costly mechanical trimming, which is still common practice, becomes redundant

Ordering Numbers

Type |

Part Number |

Package |

RoHS Compl. |

Shipping Package |

| PS09 | MNR 1783 | Dice | Yes | Waffle pack |

| PS09FN | MNR 1840 | QFN40 | Yes | |

| PS09-EVA-KIT | MNR 1785 | PCB | Yes | |

| PS09-DLC-EVA | MNR 1927 | PCB | Yes | |

| PS081 | MNR 1615 | Dice | Yes | Waffle pack |

| PS081FN | MNR 1612 | QFN56 | Yes | |

| PS081-EVA-KIT | MNR 1525 | PCB | Yes | |

| PicoProg Uni System V2.0 | MNR 1723 | PCB | Yes |

Ordering Numbers

Type |

Part Number |

Package |

RoHS Compl. |

Shipping Package |

| PS09 | MNR 1783 | Dice | Yes | Waffle pack |

| PS09FN | MNR 1840 | QFN40 | Yes | |

| PS09-EVA-KIT | MNR 1785 | PCB | Yes | |

| PS09-DLC-EVA | MNR 1927 | PCB | Yes | |

| PS081 | MNR 1615 | Dice | Yes | Waffle pack |

| PS081FN | MNR 1612 | QFN56 | Yes | |

| PS081-EVA-KIT | MNR 1525 | PCB | Yes | |

| PicoProg Uni System V2.0 | MNR 1723 | PCB | Yes |